Writing Science, June 18 (EFE).- For the moment they are a prototype, but the image sensors made of perovskite are more sensitive to light, reproduce colors with greater precision and offer a significantly higher resolution than conventional silicon-based ones.

Perovskite sensors will not only be suitable for digital cameras, but also for medical imaging analysis or for automated environmental and agricultural monitoring, according to researchers at the Swiss Federal Institute of Technology in Zurich.

The team has been investigating this type of sensor for almost a decade and has shown that they work, according to a study published in Nature.

Image sensors, typically made of silicon and integrated into all smartphones and digital cameras, distinguish colors similarly to the human eye, which individually recognizes red, green, and blue.

In image sensors, individual pixels absorb the corresponding wavelengths of each color and convert them into electrical signals.

The team led by Maksym Kovalenko has created image sensors based on lead halide perovskites, a crystalline, semiconductor material that is easy to process and whose physical properties vary depending on its exact chemical composition.

This way, if the perovskite contains a few more iodine ions, it absorbs red light, for green more bromine is added and for blue more chlorine, so filters are not needed.

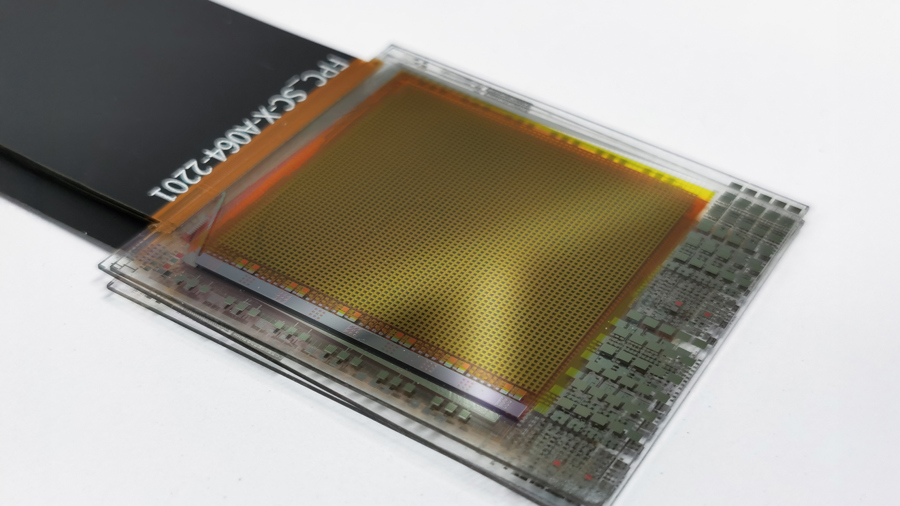

With perovskite, the pixels for red, green, and blue can be stacked on top of each other in the image sensor, unlike those of silicon, in which they are side by side.

Thanks to this arrangement, perovskite-based image sensors can, in theory, capture three times more light than conventional ones and offer three times greater spatial resolution.

Perovskite image sensors are still in the early stages of development, but with the two new prototypes created by the team, it has been shown that this technology can be miniaturized.

Researchers highlight that consumer digital cameras are not the only field of application for these sensors, as thanks to the properties of the material, they are also especially suitable for use in artificial vision.

Now, the goal is to further reduce the size and increase the number of pixels. The two prototypes have pixels between 0.5 and 1 millimeter, while those of commercial image sensors are in the micrometer range.

Spanish

Spanish